by Mark Palumbo

Director of Business Development, PanurgyOEM

Reverse Logistics Definition

Reverse logistics is defined as the set of operations associated with the return and subsequent disposition of products sold. For example, a sweater received as a birthday present doesn’t fit, it’s returned to the store and, if it hasn’t been worn and is in new condition, may be simply put back on the shelf for another consumer to purchase. A returned food item or a beauty product, if opened, will probably end up in a landfill as it cannot be resold or repurposed due to health safety concerns.

This article will focus specifically on the definition of reverse logistics as it relates to electronic products. These may be consumer electronics, professional audio gear, computers, digital displays, etc.

Electronics Reverse Logistics

Reverse logistics in the electronics industry is different than in other industries,

- Electronics products often have components with toxic materials in them and no electronics products are biodegradable so sending returned electronics to a landfill is not really a responsible move.

- The market’s thirst for the latest & greatest can create challenges when remarketing returned products that have been refurbished. Current software or firmware may not run on older products, the time it takes to remarket an electronics product is critical.

- Historically the returns process via a retailer, distributor or even direct to the manufacturer has been clumsy at best. Returns may sit in the retailer’s warehouse for quite a while before a suitable number of returns are received that are then bundled for return to the manufacturer. Distributors or manufacturers may not have the proper resources in house to inspect, analyze, repair & refurbish returned products causing even further delay. The longer these returns sit untouched, the more likely they will become obsolete and unsellable.

So, the challenge becomes how to conduct an efficient reverse logistics operation for the electronics industry that will enable a business to reclaim some value from returned electronic products?

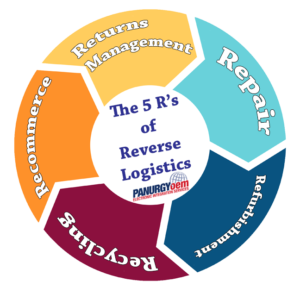

To understand that, one must understand the key components of electronics reverse logistics which we call “The 5 R’s of Reverse Logistics”.

What are the 5 “R’s” of Reverse Logistics?

1. Returns Management

Streamlining your Returns management process can pay off in many ways with better customer satisfaction at the top of the list. As we outlined above, avoiding stacks of returns in the corner of a warehouse is essential to returning either a repaired product to a customer or a refurbished product to an alternate sales channel.

To paraphrase a popular quote; “A returned product in motion tends to stay in motion, a returned product sitting on a dusty pallet tends to become junk”.

Optimizing your returns management process is key to maintaining the velocity required to make returned electronic products recommerce-ready. One solution would be to streamline your returns process so the customer, or the retailer would ship the product directly to a reverse logistics processing center. This could be a department within the manufacturer or it could be an agent or reverse logistics partner assigned to receive returns or repair requests directly. If an RMA or other return authorization is required make sure that the URL to request this is simple for the sender to find, consider putting QR codes on the user’s manual or on the original packaging.

2. Repair

Repair is sometimes overlooked as part of an electronics reverse logistics process. Depot repair requires warehouse and shop space as well as a parts inventory and trained staff. One main issue is staffing, as it’s probably difficult to forecast the volume of repairs coming to your shop, some months the volume of repairs could be very low, other months maybe the opposite is true. The unpredictability of repair demand can bring the time it takes for your products to be returned to the customer or deployed to an alternate channel to a standstill if the repair team isn’t well staffed.

3. Refurbishment

A solid refurbishment program can take returned products out of the warehouse and back in rotation creating a robust “B” stock inventory that can be used for replacement or loaner programs. A good percentage of returned electronic products don’t require repair – they were returned for other reasons, customers couldn’t figure it out, they didn’t like something about it, buyer’s remorse, and those products could be ready to be sold in an alternate channel with simple refurbishing.

Refurbishing can mean simple re-packaging or including a missing power cable or instruction manual. Proper refurbishment will include inspection of the product to determine if it needs repair, cleaning the item, looking for scratches which may put the item in a different sales channel, inspecting the overall ‘kit’ – does it have the USB cable, power block, owner’s manual, etc.. Then proper packaging to make the refurbished product ready to ship and to give it the appearance that it was professionally refurbished and not just packed in a random sized box secured by a handful of styrofoam “peanuts”.

4. Recycling

Not all returned products are salvageable. A cracked screen or a broken case may make it too expensive to refurbish the item, this is where a manufacturer – or your reverse logistics partner – must have a responsible plan for recycling electronics. Many components have toxic material and should never be introduced into a landfill particularly where it might be possible for those toxins to reach a water supply.

The US Environmental Protection Agency recommends using certified electronics recyclers to handle the disposition of used electronics. R2 and e-Stewards are the two accredited certification standards in the US. The EPA supports both programs as employing responsible best practices to provide the best processes to best recycle electronic products from an environmental, worker health and safety perspective.

More information on certified electronic recyclers can be found on the EPA website here.

5. Recommerce

This newly coined phrase, “Recommerce” includes the function of remarketing refurbished electronic products through alternate channels. One loosely related component of recomerce is to set aside a number of refurbished products for use as “B Stock” – exchanges, loaners, etc. where this type of program comes into play. Using refurbished products as “B Stock” can eliminate the practice of sending new stock out as loaners or replacements which removes any possibility that the new product used as a loaner would generate any revenue. A solid “B Stock” program, where applicable, is an excellent use of refurbished products.

A recommerce program for your refurbished items would include either setting up your own sales & marketing efforts to sell your refurbished products. Some manufacturers have avoided this in their main markets to avoid the prospect of diminishing the value of their brand.

Many manufacturers will turn to partners who are set up to market refurbished products through alternate channels such as discount stores, online vendors or partners who market only in other countries.

A good partner takes the headache out of eCommerce sales by managing finished goods inventory professionally and having the right systems in place to ship orders seamlessly. These systems should also have the ability to share pertinent metrics such as inventory, turn around time, etc. Integration to the manufacturer’s eCommerce systems is also essential to receive alerts of new orders and be able to track order status.

“A returned product in motion tends to stay in motion, a returned product sitting on a dusty pallet tends to become junk”.

Effective Reverse Logistics

To partner or not to partner?

An effective reverse logistics program is essential to enter the burgeoning recommerce market and can be a powerful way to improve customer satisfaction by providing prompt repair turnaround of loaner gear, where applicable. The prospect of setting up a proper end to end reverse logistics program can be daunting. A brief checklist of requirements to set up an internal reverse logistics program include:

- Warehouse space

- Shop/Bench space

- Parts inventory

- Trained staff and sufficient staff to handle seasonal high volumes

- Test equipment

- eCommerce Fulfillment

- Business Intelligence & Reporting

Partnering to Handle Reverse Logistics Management

A quality reverse logistics partner can address some of the obvious issues like warehouse/shop space, staffing, equipment, etc. but they can also solve some less obvious, more critical issues such as staff and cost “elasticity”.

Staff Elasticity

Return and repair volumes are not always predictable. Sometimes there are seasonal factors such as after the holiday gift giving season but there may be other non-calendar related factors such as a new release of a product with a defective or under performing component, etc. It’s challenging for your repair & refurbishment team to be fully staffed while waiting for a rush of orders. Partnering can address this by cross training team members to work on other projects at times when repair volumes are low for one product line. This eliminates the training curve for part time or replacement workers.

The “Elastic” or Variable Cost Model for Reverse Logistics

To understand variability in your reverse logistics costs you have to start with the true cost of your reverse logistics program.

The total reverse logistics cost model is as follows: Processing/Handling Costs + Logistics Costs + Credits/Replacements Cost + Asset Depreciation = Total Reverse Logistics Costs

The variable cost model targets costs for both fixed and fluctuating expenses, taking into consideration staffing, management, real estate, capital items such as shelving, forklifts, safety gear, and tools. Other costs to consider are training and the technology required to manage the overall process.

We have an excellent article on the this entitled, The Case for a Reverse Logistics Variable Cost Model

Conclusion

The case for an effective reverse logistics program for an electronics manufacturer has never been more clear. New startups focusing solely on selling refurbished electronics products are receiving huge investments. Social pressure on responsible recycling and right to repair has never been greater.

If recommerce or advanced repair is on your whiteboard this year, please reach out to us at 973-625-4056 and we’ll arrange a free strategy session to help you explore your options.